Gate valves from Alloy Valve Stockist

Looking for valves in exotic alloys? We stock gate valves in 6MO 6moly), 254 SMO, 904L, AL-6XN, Alloy 20, Aluminum Bronze, Duplex, Hastelloy, Incoloy, Inconel, Monel, Nickel alloy, Austenitic stainless steel, Super Duplex, Titanium, Uranus B6 and Zirconium.

See also:

• Bellow seal gate valves

• Pressure seal gate valves

• Knife gate valves

• Parallel slide gate valves

GATE VALVES .- Gate valves are used when a straight-line flow of fluid and minimum restriction is desired. Gate valves are so named because the part that either stops or allows flow through the valve acts somewhat like the opening or closing of a gate and is called, appropriately, the gate. The gate is usually wedge shaped. When the valve is wide open, the gate is fully drawn up into the valve, leaving an opening for flow through the valve the same size as the pipe in which the valve is installed. Therefore, there is little pressure drop or flow restriction through the valve. Gate valves are not suitable for throttling purposes since the control of flow would be difficult due to valve design and since the flow of fluid slapping against a partially open gate can cause extensive damage to the valve. Except as specifically authorized, gate valves should not be used for throttling.

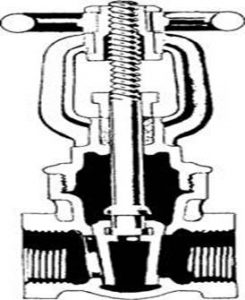

Gate valves are classified as either RISING-STEM or NON RISING-STEM valves. On the non rising-stem gate valve shown in figure-2 the stem is threaded on the lower end into the gate. As the handwheel on the stem is rotated, the gate travels up or down the stem on the threads, while the stem remains vertically stationary. This type of valve almost always has a pointer-type indicator threaded onto the upper end of the stem to indicate valve position.

Figure 2.-Cutaway view of a gate valve (non-rising-stem type).

The rising-stem gate valve, shown in figure has the stem attached to the gate; the gate and stem rise and lower together as the valve is operated.

Gate valves used in steam systems have flexible gates. The reason for using a flexible gate is to prevent binding of the gate within the valve when the valve is in the closed position. When steam lines are heated, they will expand, causing some distortion of valve bodies. If a solid gate fits snugly between the seat of a valve in a cold steam system, when the system is heated and pipes elongate, the seats will compress against the gate, wedging the gate between them and clamping the valve shut. This problem is overcome by use of a flexible gate (two circular plates attached to each other with a flexible hub in the middle). This design allows the gate to flex as the valve seat compresses it, thereby preventing clamping.

Source: “Inspection of Piping Systems“.

A total containment solution is available with the installation of a bellow seal gate valve constructed to positively eliminate any leak paths at the bonnet joint and packing. The valve, with its bellows and seal welded construction, totally confines the flow media within the valve pressure boundary. The valve packing is totally isolated by the bellows from the flowing medium and serves in a ”back up” role only.

Bellow seal globe valves seek to be zero emission and maintenance free. An uninterrupted metallic barrier is positioned between the piping and the environment. The components that during valve operation are subject to relative movements are welded onto the extremities of a metallic bellows that absorbs and compensates the shiftings. Hence these valves are suitable for any fluid and are recommended when zero emission characteristics are required to protect the environment and the health of the workers from pollutive leaks, to prevent expensive wastes due to loss of energy and fluid, and to eliminate the not negligible cost of replacement of the packing. In conclusion, the valves are particularly suitable for dangerous, inflammable, lethal and explosive media.

Pressure seal construction is adopted for valves for high pressure service, typically in excess of above 170 bar. The unique feature about the pressure seal Bonnet is that the body-Bonnet joints seals improves as the internal pressure in the Valve increases, compared to other constructions where the increase in internal pressure tends to create leaks in the body-bonnet joint.

Relying on fairly simple design principles, pressure seal valves have proven their capability to handle increasingly demanding fossil and combined-cycle steam isolation applications, as designers continue to push boiler, HRSG, and piping system pressure/temperature envelopes. Pressure seal valves are typically available in size ranges from 2 inches to 24 inches and ASME B16.34 pressure classes from #600 to #2500, although some manufacturers can accommodate the need for larger diameters and higher ratings for special applications.

Pressure seal valves are available in alloy grades for over 500�C. The pressure seal design concept can be traced back to the mid-1900s, when, faced with ever increasing pressures and temperatures (primarily in power applications), valve manufacturers began designing alternatives to the traditional bolted-bonnet approach to sealing the body/bonnet joint. Along with providing a higher level of pressure boundary sealing integrity, many of the pressure seal valve designs weighed significantly less than their bolted bonnet valve counterparts.

Gate valves and knife valves are advantageous in applications involving slurries, as their “gates” can cut right through the slurry. They are also used in applications that involve viscous liquids such as heavy oils, light grease, varnish, molasses, honey, cream and other non-flammable viscous liquids. They are available in large sizes to better handle thick flow. However, gate valves do have low-pressure limitations, and are not optimal in applications that require cleanliness or sanitary conditions. They are excellent for use anywhere a shutoff valve is needed. They can also be used where throttling capabilities are desired, although this is not generally recommended as erosion of the seat and disc occurs due to the vibrations of the disk in throttling applications.

Gate valves are usually divided into two types: parallel and wedge-shaped. The parallel gate valve uses a flat disc gate between two parallel seats, upstream and downstream. Knife valves are of this type, but with a sharp edge on the bottom of the gate to shear entrained solids or separate slurries.

In the double-disk parallel-seat type, the valve is closed by lowering the disks from the valve neck to a height equal to that of the valve seats. Once so positioned, an inclined plane mounted between the two disks coverts downward stem force into axial force and presses the parallel disks firmly against the valve seats sealing the two openings. These types of valve design can accommodate asymmetric or angularly misaligned valve seats.

Wedge-shaped gate valves and knife valves use two inclined seats and a slightly mismatched inclined gate allowing for tight shut-off. Disk flexibility is inherent to the split wedge design. This flexibility allows the split wedge to seal more easily and it reduces stickiness between the sealing surfaces in cases where the valve seats are angularly misaligned.

A Gate Valve, or Sluice Valve, as it is sometimes known, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar. The gate faces can form a wedge shape or they can be parallel. Gate valves are sometimes used for regulating flow, but many are not suited for that purpose, having been designed to be fully opened or closed. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

Gate valves are characterised as having either a rising or a nonrising stem. Rising stems provide a visual indication of valve position. Nonrising stems are used where vertical space is limited or underground.

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

Another type of bonnet construction in a gate valve is pressure seal bonnet. This construction is adopted for valves for high pressure service, typically in excess of 15 MPa (2250 psi). The unique feature about the pressure seal bonnet is that the body – bonnet joints seals improves as the internal pressure in the valve increases, compared to other constructions where the increase in internal pressure tends to create leaks in the body-bonnet joint.

Gate valves normally have flanged ends which are drilled according to pipeline compatible flange dimensional standards. Cast iron, cast carbon steel, gun metal, stainless steel, alloy steels, and forged steels are different materials from which gate valves are constructed.

Gate valves and knife valves are advantageous in applications involving slurries, as their “gates” can cut right through the slurry. They are also used in applications that involve viscous liquids such as heavy oils, light grease, varnish, molasses, honey, cream and other non-flammable viscous liquids. They are available in large sizes to better handle thick flow. However, gate valves do have low-pressure limitations, and are not optimal in applications that require cleanliness or sanitary conditions. They are excellent for use anywhere a shutoff valve is needed. They can also be used where throttling capabilities are desired, although this is not generally recommended as erosion of the seat and disc occurs due to the vibrations of the disk in throttling applications.

Gate valves are usually divided into two types: parallel and wedge-shaped. The parallel gate valve uses a flat disc gate between two parallel seats, upstream and downstream. Knife valves are of this type, but with a sharp edge on the bottom of the gate to shear entrained solids or separate slurries.

In the double-disk parallel-seat type, the valve is closed by lowering the disks from the valve neck to a height equal to that of the valve seats. Once so positioned, an inclined plane mounted between the two disks coverts downward stem force into axial force and presses the parallel disks firmly against the valve seats sealing the two openings. These types of valve design can accommodate asymmetric or angularly misaligned valve seats.

Wedge-shaped gate valves and knife valves use two inclined seats and a slightly mismatched inclined gate allowing for tight shut-off. Disk flexibility is inherent to the split wedge design. This flexibility allows the split wedge to seal more easily and it reduces stickiness between the sealing surfaces in cases where the valve seats are angularly misaligned.

A Gate Valve, or Sluice Valve, as it is sometimes known, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar. The gate faces can form a wedge shape or they can be parallel. Gate valves are sometimes used for regulating flow, but many are not suited for that purpose, having been designed to be fully opened or closed. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

Gate valves are characterised as having either a rising or a nonrising stem. Rising stems provide a visual indication of valve position. Nonrising stems are used where vertical space is limited or underground.

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

Another type of bonnet construction in a gate valve is pressure seal bonnet. This construction is adopted for valves for high pressure service, typically in excess of 15 MPa (2250 psi). The unique feature about the pressure seal bonnet is that the body – bonnet joints seals improves as the internal pressure in the valve increases, compared to other constructions where the increase in internal pressure tends to create leaks in the body-bonnet joint.

Gate valves normally have flanged ends which are drilled according to pipeline compatible flange dimensional standards. Cast iron, cast carbon steel, gun metal, stainless steel, alloy steels, and forged steels are different materials from which gate valves are constructed.