Butterfly valves from Alloy Valve Stockist

Looking for valves in exotic alloys? We stock butterfly valves in 6MO 6moly), 254 SMO, 904L, AL-6XN, Alloy 20, Aluminum Bronze, Duplex, Hastelloy, Incoloy, Inconel, Monel, Nickel alloy, Austenitic stainless steel, Super Duplex, Titanium, Uranus B6 and Zirconium.

See also:

• Triple eccentric butterfly valves

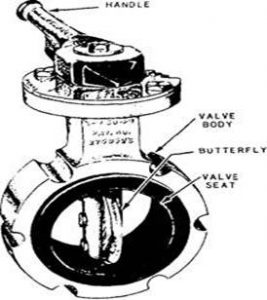

BUTTERFLY VALVES .- The butterfly valve, one type of which is shown in figure -3 may be used in a variety of systems aboard ship. These valves can be used effectively in lube oil, and chill water systems. The butterfly valve is light in weight, relatively small, relatively quick-acting, provides positive shut-off, and can be used for throttling.

The butterfly valve has a body, a resilient seat, a butterfly disk, a stem, packing, a notched positioning plate, and a handle. The resilient seat is under compression when it is mounted in the valve body, thus making a seal around the periphery of the disk and both upper and lower points where the stem passes through the seat. Packing is provided to form a positive seal around the stem for added protection in case the seal formed by the seat should become damaged.

To close or open a butterfly valve, turn the handle only one quarter turn to rotate the disk 90°. Some larger butterfly valves may have a hand wheel that operates through a gearing arrangement to operate the valve. This method is used especially where space limitation prevents use of a long handle.

Butterfly valves are relatively easy to maintain. The resilient seat is held in place by mechanical means, and neither bonding nor cementing is necessary. Because the seat is replaceable, the valve seat does not require lapping, grinding, or machine work.

Source: “Inspection of Piping Systems“.

Triple eccentric butterfly valves

The triple eccentric (or triple offset) butterfly valve design prevents galling and scratches between the metal seat and the metal disc due to its unique design. The only time where the seal comes into contact with the seat is at the point of complete closure. Triple offset valves are generally used in applications which require bi-directional tight shut-off in oil and gas, LNG/NPG terminal and tanks, chemical factories, and shipbuilding. This design is also used for dirty/heavy oil to prevent extrusion.