Ball valves from Alloy Valve Stockist

Looking for valves in exotic alloys? We stock ball valves in 6MO 6moly), 254 SMO, 904L, AL-6XN, Alloy 20, Aluminum Bronze, Duplex, Hastelloy, Incoloy, Inconel, Monel, Nickel alloy, Austenitic stainless steel, Super Duplex, Titanium, Uranus B6 and Zirconium.

See also:

• Metal-seated ball valves

• Three-way ball valves

• Trunnion mounted ball valves

• Wafer ball valves

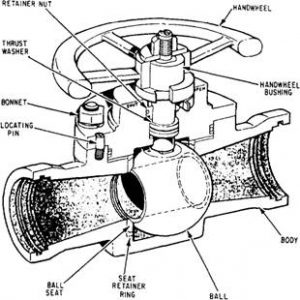

BALL VALVES .- Ball valves are stop valves that use a ball to stop or start the flow of fluid. The ball (fig 5) performs the same function as the disk in the globe valve. When the valve handle is operated to open the valve, the ball rotates to a point where the hole through the ball is in line with the valve body inlet and outlet. When the valve is shut, which requires only a 90-degree rotation of the hand wheel for most valves, the ball is rotated so the hole is perpendicular to the flow openings of the valve body, and flow is stopped.

Most ball valves are of the quick-acting type (requiring only a 90-degree turn to operate the valve either completely open or closed), but many are planetary gear operated. This type of gearing allows the use of a relatively small hand wheel and operating force to operate a fairly large valve. The gearing does, however, increase the operating time for the valve. Some ball valves contain a swing check located within the ball to give the valve a check valve feature.

Source: “Inspection of Piping Systems“.

Compared to ball valves that use soft seats such as RPTFE, metal seated ball valves are only used in the severe service condition such as high temperature, high erosion or abbrasion, or slurries. In the petrochemical sector, the soft seated ball valve is used. This type of seat will provide an excellent sealing capability with a fair life time in clean service application, while the metal seated ball valve is used when the soft seated ball valve can’t handle anymore the process condition.

Three-way ball valves have an L- or T-shaped hole through the middle. The different combinations of flow are shown in the figure. It is easy to see that a T valve can connect any pair of ports, or all three, together, but the 45 degree position which might disconnect all three leaves no margin for error. The L valve can connect the center port to either side port, or disconnect all three, but it cannot connect the side ports together.

Multi-port ball valves with 4 ways, or more, are also commercially available, the inlet way often being orthogonal to the plane of the outlets. For special applications, such as driving air-powered motors from forward to reverse, the operation is performed by rotating a single lever four-way valve. The 4-way ball valve has two L-shaped ports in the ball that do not interconnect, sometimes referred to as an “�” port.

Ball valves in sizes up to 2 inch generally come in single piece, two or three piece designs. One piece ball valves are almost always reduced bore, are relatively inexpensive and generally are throw-away. Two piece ball valves are generally slightly reduced (or standard) bore, they can be either throw-away or repairable. The 3 piece design allows for the center part of the valve containing the ball, stem & seats to be easily removed from the pipeline. This facilitates efficient cleaning of deposited sediments, replacement of seats and gland packings, polishing out of small scratches on the ball, all this without removing the pipes from the valve body. The design concept of a three piece valve is for it to be repairable.

Trunnion mounted ball valves are more expensive than floating design, but there are two factors that heavily influence the choice:

Size and pressure class: the larger the valve and the higher the pressure class, the more the service will lend itself to a trunnion type ball valve. This point of inflection generally comes at 1″ 2500#, 4″ 600# or 10″ 150#.

Service condition: the more extreme the condition, the better apt the trunnion type ball valve is to handle it. High temperature or abrasive service, for example, is recommended, particularly for larger size valves.

Trunnion mounted ball valves offer lower torque than floating ball valves, and offer more consistent service over time, but are more complex and hence require a more expensive maintenance routine than standard ball valves.

Compared to standard design ball valves, wafer ball valves save space and weight, and hence cost less to manufacture.